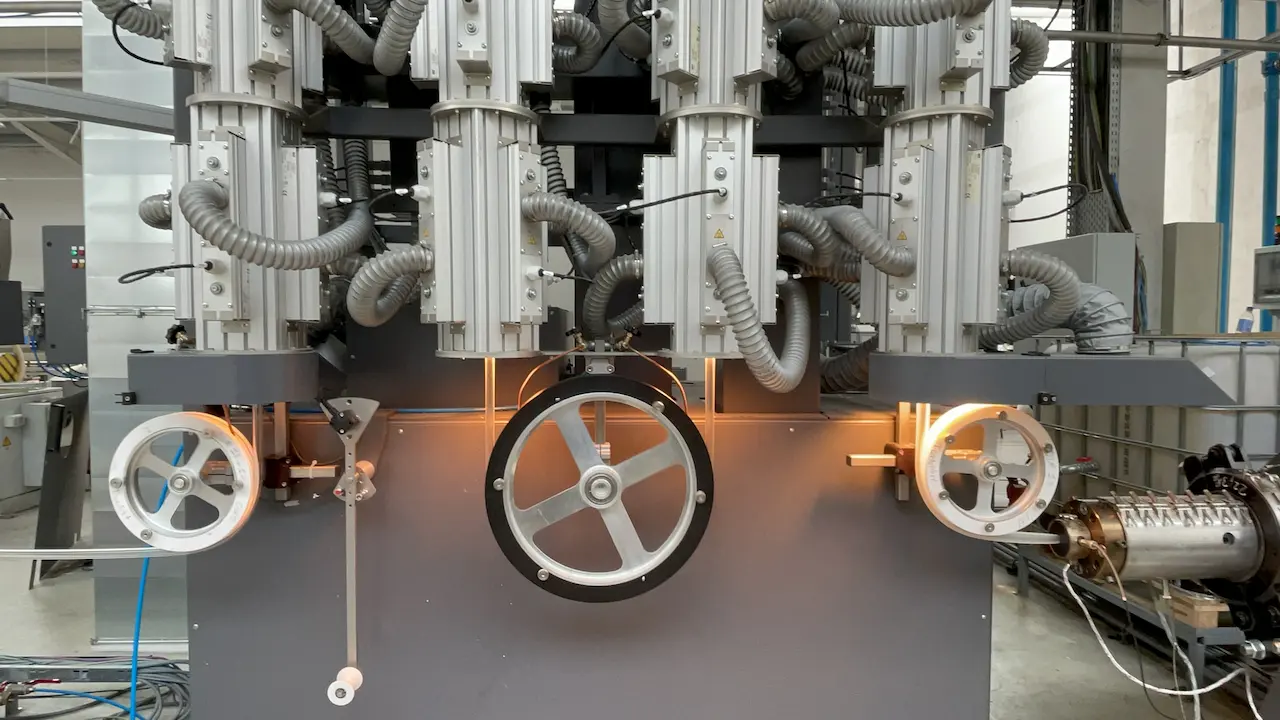

Cutting-edge Technology

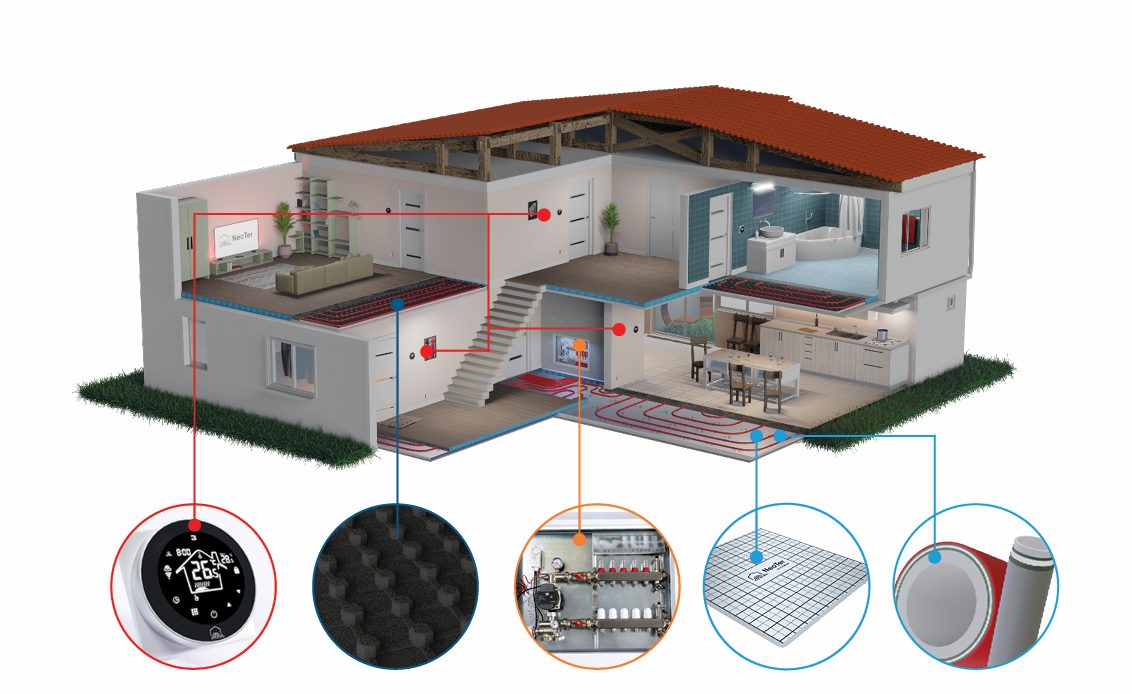

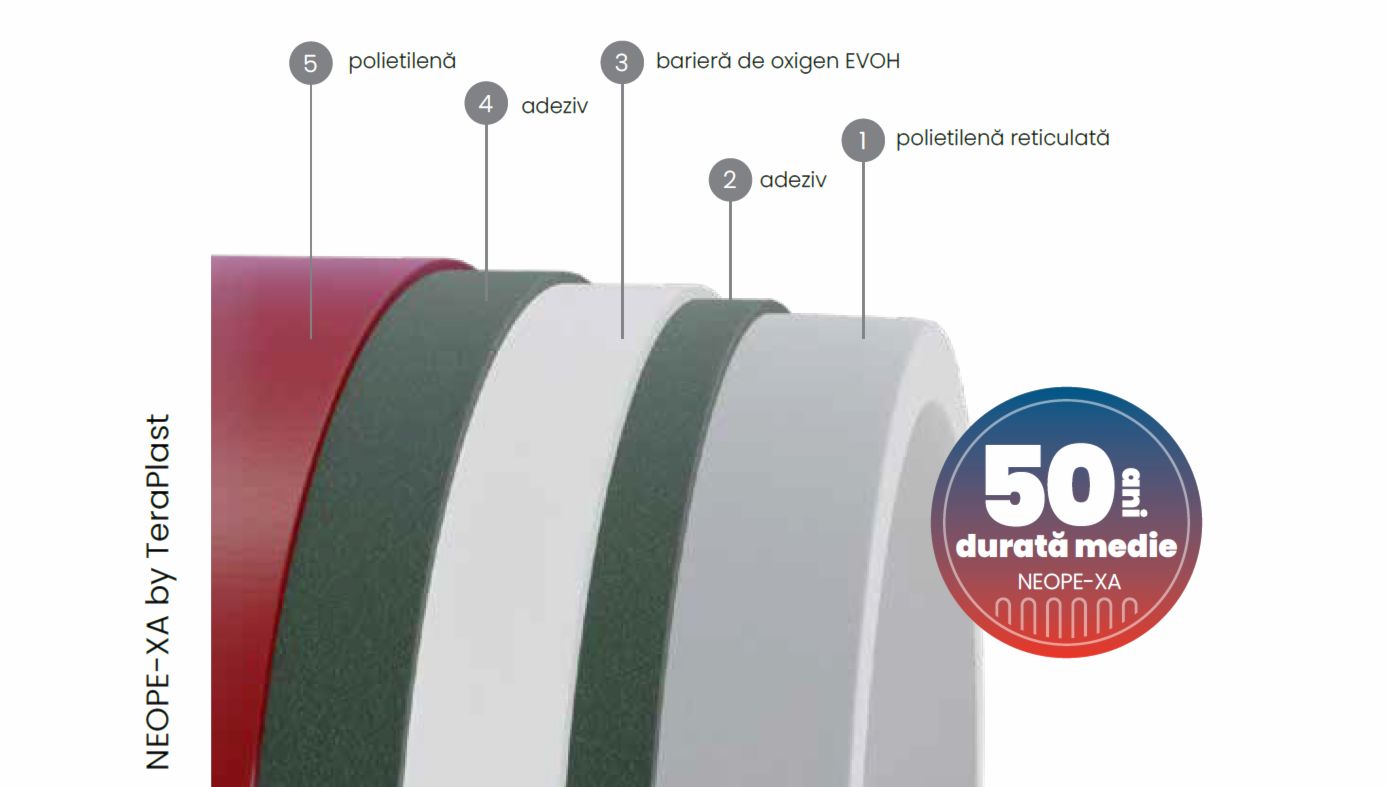

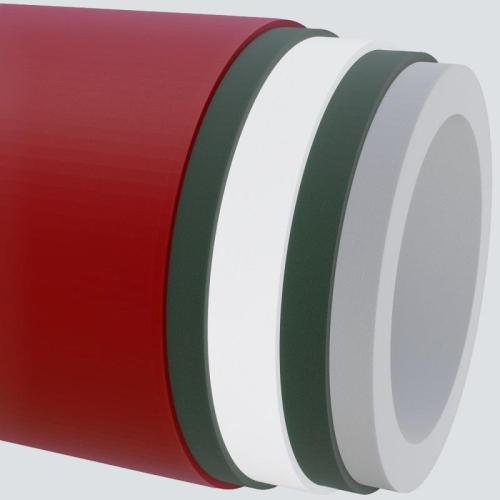

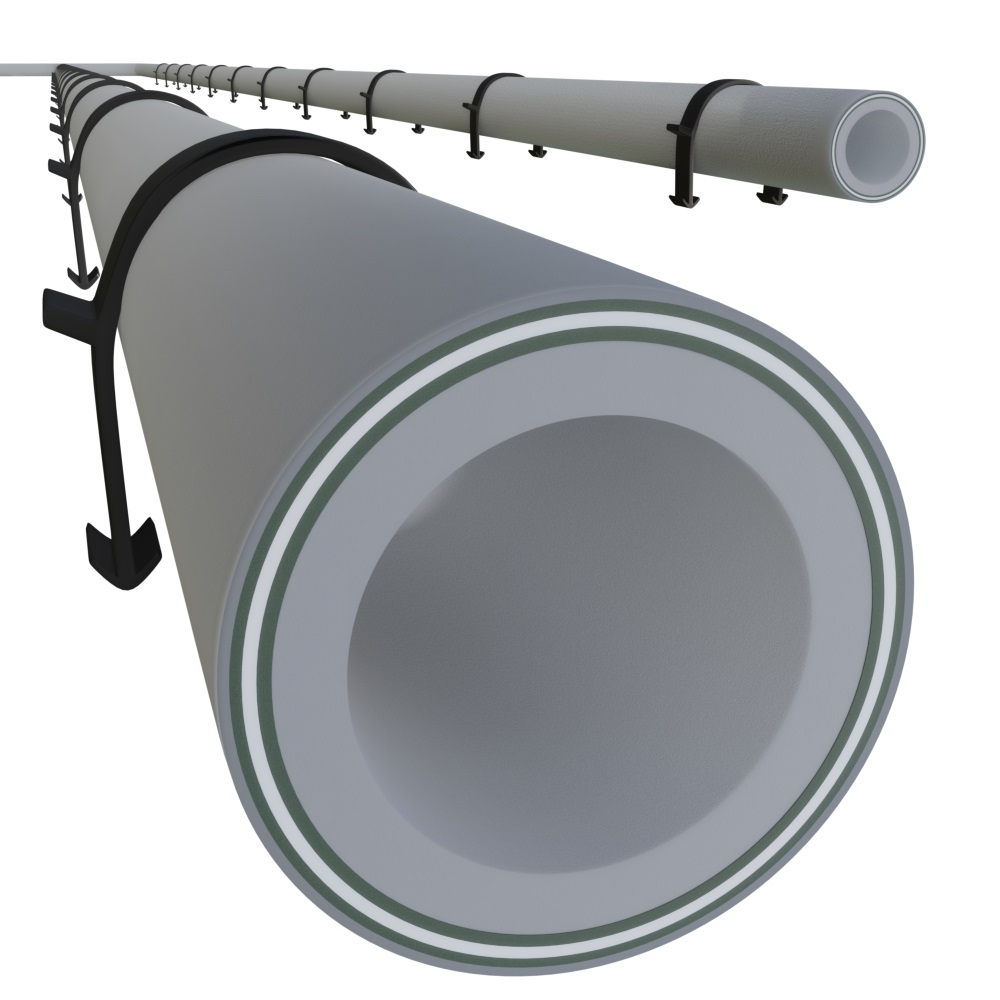

For the NeoTer underfloor heating system, we use only high-quality raw materials, guaranteed by manufacturers. The main component of the system is NEOPE-XA pipes – cross linked polyethylene with peroxides – and NEOPE-RT TYPE II – “raised temperature” polyethylene. These are the most used pipe types for underfloor heating systems.